Does Rain Ruin Sealcoating?

Sealcoating is an economical, attractive way to refresh, upgrade and protect asphalt and concrete driveways and other paved areas around your home or business. For the best results, sealcoating must be done during warm, dry weather to ensure the coating adheres to the substrate.

If you are planning to sealcoat your driveway, schedule it when weather conditions will enhance curing. Your contractor should offer flexible scheduling and provide recommendations that overcome the challenges of rain, humidity, overcast days and fluctuating temperatures.

The professional crew at NWS House Washing And Asphalt Seal Coating work closely with clients in the Twin Tiers area to achieve optimum sealcoating results. We schedule sealcoating to avoid rain before and after driveway sealing and take advantage of sunny, breezy days that help sealcoating to dry. When properly done, your newly sealed driveway will provide an impermeable barrier to protect your pavement for several years.

What Happens if It Rains Right Before Sealcoating?

Sealcoating must be applied to a dry surface. If the pavement is wet, the coating will not adhere. If it rains beforehand, your contractor will evaluate the amount of saturation and recommend when to apply sealant.

The Importance of a Dry Surface

The climate and weather conditions affect the long-term performance of sealcoating. The pavement must be completely dry before applying sealant. A wet surface prevents the sealant from binding to the asphalt. Water in the pavement affects durability and appearance.

Moisture's Effect on Sealcoat Quality

Sealant contains a large proportion of water, which must evaporate during curing. Evaporation of water in the mix allows particles to bind to one another and the pavement. Water on the pavement retards evaporation. Moisture trapped under the sealcoat can cause bubbles or blisters, creating an uneven seal that shortens the service life and can cause the coating to fail.

Sealant dries in layers from top to bottom. As layers cure, the sealant shrinks, forming a tight, waterproof bond. Although the coating may feel dry after a few hours, complete curing takes up to 24 hours. Curing is not complete until 100% of the moisture is released from the sealant. Curing time depends on the consistency of the mix, thickness of coverage, ambient temperature, relative humidity and wind speed.

Rain within 12 hours after sealing a driveway can wash away the coating before it dries. Heavy cloud cover affects curing because clouds contain water vapor. Saturated air cannot absorb the moisture released from sealant, which prolongs the curing process.

Preparation Guidelines

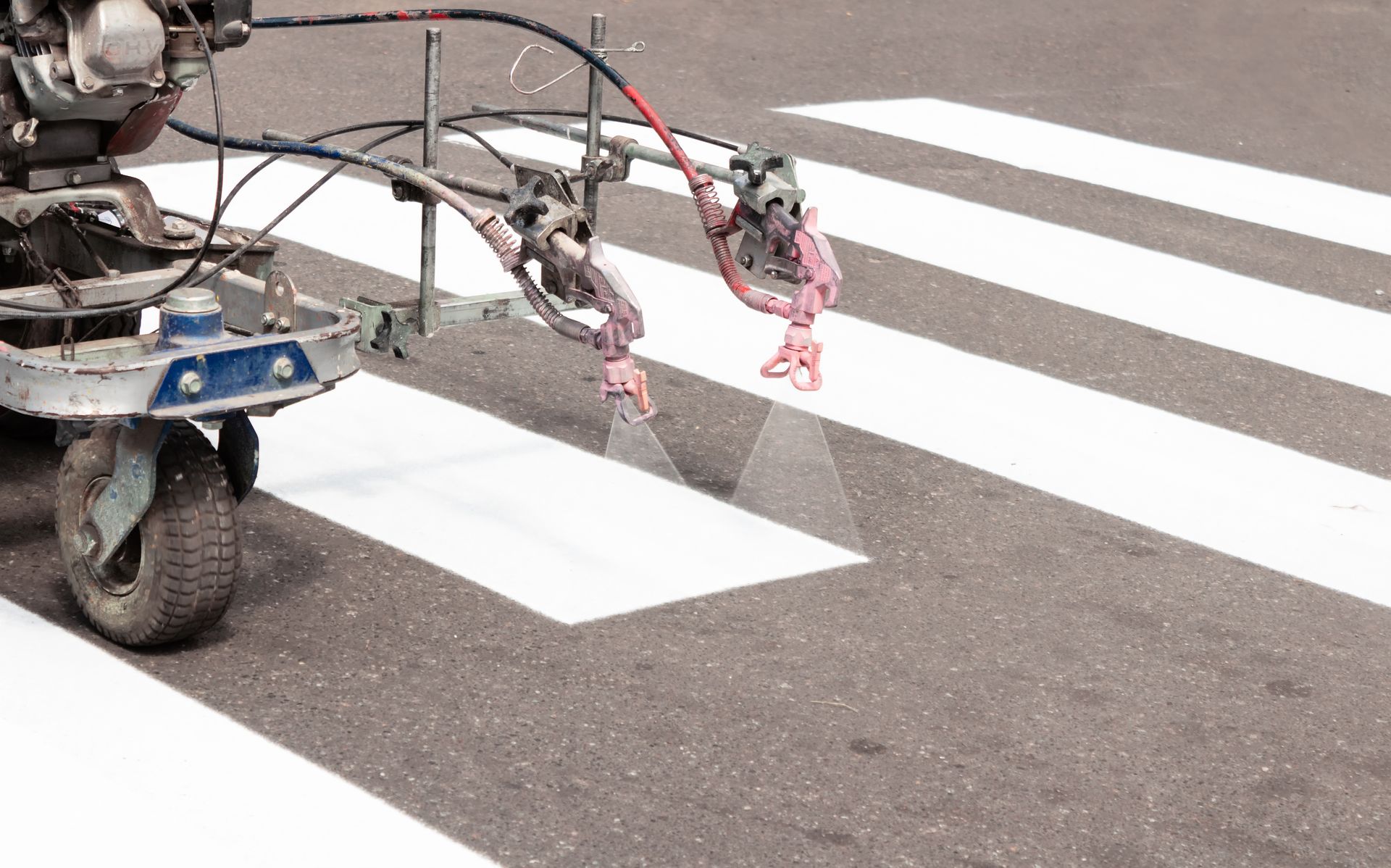

Professionals are trained to determine when the pavement is dry enough to apply sealcoat. Your contractor may use special tools and tests to determine when pavement is ready for sealcoating and will schedule accordingly.

Before sealing, you must prepare your driveway.

- Sweep away debris and dust. If the pavement is dirty, power wash at low pressure to remove dust and dirt.

- Remove grass and other vegetation growing on the pavement.

- Trim grass at the edges of the pavement.

- Treat oil and other stains.

- Repair cracks and potholes.

- Ensure the pavement is completely dry.

Experts recommend waiting at least 90 days and as long as one year before sealcoating a new driveway to ensure the asphalt is completely cured and ready for sealing.

Can You Sealcoat a Wet Driveway?

We recommend scheduling the job when no rain is forecast for 24 to 48 hours. However, if light rain is followed by warm, sunny weather, we will evaluate whether conditions are favorable for application.

Challenges in Sealing Wet Surfaces

Sealcoating dries from top to bottom in thin layers of film. Between 80% and 90% of water loss occurs during the early stages of curing. The lowest layers take longer to dry. If the sealant does not completely dry, the service life will be shortened. That is why experts recommend sealing when there is little chance of rain for 12 hours after sealing a driveway.

Sealcoating Innovations for Damp Surfaces

Tailoring the sealcoat mix optimizes results. Our crews mix components to create a sealant consistency that achieves the best results for each unique situation. Sealcoating contains approximately 70% water by volume, aggregates and additives. Aggregates help create a uniform, attractive surface and improve traction.

Additives enhance the physical properties of the mix. Rubber and polymer additives improve flexibility and durability. Some additives speed up drying time, which is helpful when applying sealants in adverse conditions. High-quality asphalt emulsion sealers often include additives that enhance durability.

Additives can be used with refined tar-based and asphalt-based sealants. Manufacturers of high-grade commercial sealants often add performance-enhancing polymers. If we must sealcoat in damp conditions, we choose products that work well in the Twin Tiers region and suit the situation.

Best Practices When Faced With Wet Conditions

Experienced contractors recommend the best time and method to apply sealant when dealing with wet conditions. We use low-tech tools, including squeegees and brooms, to slough off surface water to speed up drying the pavement before sealcoating. Because high humidity affects the release of moisture from the sealant, we may elect to apply thin coats of sealant and allow more drying time between coats.

Contractors may use specialty equipment, such as commercial air dryers, blowers or heaters, when faced with wet conditions. Heavy-duty equipment can dry asphalt pavement in less than an hour.

The optimum time to apply sealant is early or mid-morning on a dry surface when the temperature is above the dew point. If there is early morning fog, sealant can be applied later as the day warms up and moisture burns off. Late afternoon applications allow sealant to dry overnight. Initial drying occurs in the first four to eight hours after application. The sealant should be kept dry during this period.

How Long Does It Take Asphalt to Dry After It Rains?

The amount of time it takes for asphalt to dry depends on the slope of the pavement, its condition, the ambient temperature and amount of rainfall. Good drainage around the pavement helps it dry more quickly.

Variables That Affect Drying Time

Several variables affect drying time. Pavement will dry quickly from a light mist, especially when followed by warm, sunny weather. Pavement subjected to heavy rain that percolates into the substrate may require a full day to dry. Heat in the pavement speeds drying. Wind lifts and disperses moisture lying on or close to the pavement's surface, which speeds up drying.

The slope of the pavement affects drying time because water runs off slopes more quickly than from flat surfaces. Drying takes longer during overcast or humid conditions. As a local contractor, we are familiar with the variables in the Twin Tiers region that affect drying time. We will inform you when the asphalt is dry enough to apply sealant.

Physical Signs of Dry Asphalt

Experienced contractors use tactile and visual evaluations to determine when asphalt is dry enough to seal. The pavement will be dry to the touch. We examine the color because water darkens asphalt. When it is dry, it will return to its normal color.

For industrial applications, contractors may use the water-break test to evaluate the presence of surface contaminants that can affect the ability of sealant to adhere to the pavement.

The Role of Porosity in Drying

Conventional asphalt has a low porosity with a void space of approximately 2% to 3%. Low porosity allows water to flow off the surface quickly. Porous asphalt has a void space of approximately 16%, allowing water to flow through the pores and drain into soils. Porous materials become more saturated and take longer to dry.

Pavement in areas that retain water or are frequently flooded requires longer drying. For best results, work with an experienced contractor who can evaluate the conditions and recommend ways to dry the asphalt to achieve optimum conditions. Because heat, sunlight and low humidity release moisture, your contractor may recommend waiting to seal your driveway until weather conditions are favorable.

What Is The Best Weather to Sealcoat a Driveway?

Warm temperatures, low humidity and sunlight are the best weather conditions for sealcoating. Forecasts should be for clear, dry weather for 24 to 48 hours before and after application.

Ideal Temperature Ranges for Sealcoating

Ideal weather conditions include:

•Dry, warm weather between 50 degrees F and 90 degrees F.

•No rain forecast for 24-48 hours before and after application.

•Direct sunlight.

•Relative humidity below 60%.

•Low chance of early morning dew.

•Light wind.

Ideally, sealcoating should be applied when temperatures start at approximately 70 degrees and increase throughout the day. Surface and air temperatures should remain above 50 degrees F within 24 hours of application.

Consistent temperatures during the drying phase are important. Properly cured sealants are smooth and free of imperfections, characteristics that enhance durability and performance. If the weather is too hot, the sealant dries too quickly. A sudden release of moisture creates pinholes in the membrane. The binders and aggregates do not flow or fuse to form a continuous, impervious film. Cold weather prevents the particles from softening and creating a continuous membrane. The sealant will fail if it freezes.

Humidity and Its Effect on Sealcoating

Sealcoating should be done when humidity is below 60%. High humidity slows down the evaporation of water from the sealant.

When relative humidity is 50%, only half of the air can absorb moisture. As relative humidity increases, the ability of air to absorb moisture decreases. The higher the humidity, the longer the drying time. At 80% humidity, curing time triples. Sealant should not be applied when humidity is above 90%.

If sealant must be applied when humidity is high, experienced professionals have several options to assure performance:

•Reduce the amount of water in the mix.

•Apply thinner coats.

•Increase drying time between coats.

•Adjust the ratio of sand and other aggregates.

•Use fast-dry sealants.

The Role of Sunlight in the Sealcoating Process

Sunlight helps sealcoating cure because it heats the pavement surface, which speeds up drying time. However, temperatures above 90 degrees F combined with direct sunlight can make the pavement too hot and affect performance.

On cloudy days when there is no sunlight to raise the temperature of the pavement, drying will take more time. Humidity is often higher on overcast days, which retards the release of moisture from the sealant.

Seasonal Considerations for Sealcoating

For best results, sealcoating must be done under warm, dry conditions. In the Twin Tier region, the best time to apply sealcoating is during the late spring, summer and early fall when temperatures remain above 50 degrees F and there is not much chance of rain.

In our service area, June, July and August have temperatures suitable for sealcoating. There is less cloud cover, with August typically having the clearest skies. During the summer and early September, more sunshine and light winds help sealcoating dry quickly.

Because weather conditions in the Twin Tiers region can affect the quality and performance of sealcoating, both contractors and clients must be flexible in scheduling.

For more information about sealcoating, call NWS House Washing And Asphalt Seal Coating. We provide free estimates.